Brands moving to flexible packaging increasingly evaluate roll stock film printed with water-based ink for sustainability, worker safety, and regulatory reasons. To succeed, teams must understand materials, press dynamics, food-safety testing, and an actionable pilot plan.

Today, Zhongjia Printing, a roll stock film manufacturer based on water-based ink, is bringing this guide to you and telling you what you need to know about water-based printing by the way.

What is Roll Stock Films

Roll stock film is a continuous flexible film supplied in roll form to bag-making filling, sealing (FFS) equipment. It can be single-layer (mono) or multi-layer coextruded (PET/PE, BOPP/PE, PET/EVOH/PE, etc.). Brand owners prefer roll film because it can reduce storage processing (rolls are easy to stack), support multiple bag types (pillow, vertical, flat bottom), and can be smoothly integrated into automated FFS production lines, achieving high output and low waste. Pre-selecting a suitable coil structure can avoid subsequent sealing, blocking, and printing issues.

Why Choose Water-based Ink for Roll Stock Film

Water-based ink cuts VOC emissions on press, improving operator safety and easing environmental compliance. For brands, this supports sustainability claims and can lower solvent disposal and fire-safety costs. Modern water-based systems also reduce odor and often simplify permitting in regions with strict solvent limits. When matched to the correct substrate and dryer setup, performance approaches solvent or UV systems while delivering a markedly cleaner pressroom environment.

Chemistry & Formulation Basics You Should Know

Water-based inks typically use acrylic or polyurethane dispersions as binders and provide color with pigment powders. The formulator will add defoamers, wetting agents, and rheological modifiers to control viscosity and dot expansion. The key decisions that brands need to make include: requiring the use of food grade pigments when there is a possibility of food contact; Inquire with suppliers about the screening status of Unintentionally Added Substances (NIAS); And request a Technical Data Sheet (TDS), which should list the required solid content, pH value, and recommended printing viscosity range for flexo plates.

Printing Technologies and Press Requirements

Flexographic presses are the primary platform for water-based ink on roll stock because they balance transfer efficiency and dryer compatibility. Gravure and hybrid presses can work, but may need modified solvent-free ink train components. High-speed rotogravure lines often favor solvent/UV, so don’t assume a direct swap—evaluate oven capacity and web tension control before changing ink systems. Ask your printer for achieved line speeds on the same substrate with comparable ink coverage.

Substrate Compatibility & Surface Pretreatment

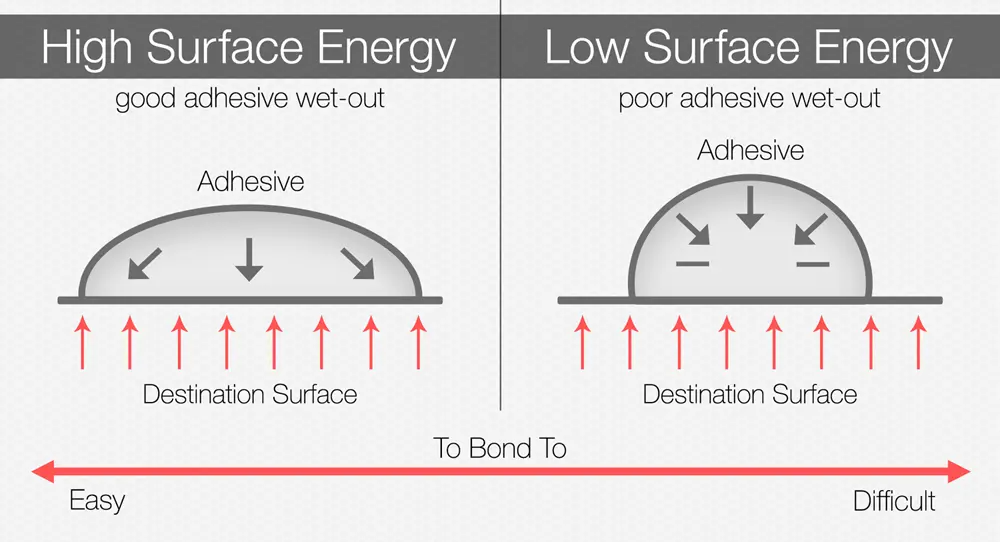

Low surface-energy films (PE, some BOPP) require corona or plasma treatment to raise surface energy for wetting. Metallized films usually need a primer to accept water-based ink. Specify target surface energy (ask for dynes/cm value from supplier) and require adhesion tests (cross-hatch, rub) on the exact film lot. Small differences in film additives or anti-static layers can make adhesion vary—always test the production film sample rather than relying on generic claims.

Drying Strategy and Line-speed Trade-offs

Drying water takes energy: common oven setups combine IR, hot-air convection, and chill rollers. The correct oven balance prevents blocking (wet ink sticking) and web distortion. Faster line speeds need proportionally higher dryer capacity and careful control of ink solids and tack. During pilot, track oven energy (kW), web temperature, and the shortest dwell time that yields no blocking—these numbers define realistic full-scale throughput.

Food Safety, Migration & Regulatory Testing

Ink components can migrate; for food-adjacent packaging, insist on finished-pouch migration tests (overall and specific), NIAS screening, and sensory panels when aroma transfer is a risk. Require suppliers to provide third-party lab reports referencing applicable standards (EU, FDA) and a certificate of compliance for pigments and additives. For any claim about “food-safe” inks, demand batch-level documentation and confirm which part of the package (outer printed surface vs inner sealant) is covered.

Quality Control & Color Management

Color consistency with water-based ink relies on ICC profiles, spectral density measurement, and ΔE tolerances. Implement inline web inspection and humidity/temperature logging since environmental shifts change color and drying. Common defects—mottling, pinholing, banding—are often linked to wrong anilox cell selection, incorrect viscosity, or poor pretreatment. Define acceptance criteria (e.g., ΔE ≤ 2, no more than X% surface defects) in the supplier SLA.

Implementation Roadmap: Lab to Full Scale

A staged pilot reduces risk:

- Lab trials — swatches on candidate films for adhesion, rub, migration.

- Press pilot — short rollstock runs on the actual press; capture oven settings and line speed.

- FFS pilot — run printed rolls through sealing and filling equipment; check sealability and blocking.

- Filled-sample testing — shelf-life, sensory, shipping simulation.

- Scale-up — freeze process parameters, add color warranty, and QA gates. Track KPIs: line speed (m/min), print yield, ΔE, seal strength, migration pass rate, and energy per 1,000 m.

About Zhongjia Printing

Zhongjia Printing is positioned as an expert flexible packaging manufacturer, with a strong focus on sustainability and innovation. Through the use of water-based ink printing, our roll stock films reduce VOC emissions and minimize environmental impact while maintaining vivid color performance and product safety.

We specialize in custom water-based ink roll stock film solutions, helping brands achieve packaging that is both eco-friendly and market-ready, balancing high-quality visuals with responsible production practices.

Conclusion

Adopting water-based ink for custom roll stock film is a pragmatic sustainability step, but success depends on cross-functional alignment—brand, converter, ink supplier, and FFS operator must collaborate. Run the staged pilot, demand finished-pouch testing, and lock process parameters into contracts: with the right controls, water-based ink enables cleaner pressrooms, stronger sustainability claims, and competitive packaging performance.

FAQs

Q: Will switching to water-based inks slow my press?

A: It can if dryers are insufficient. With correct oven design most flexo lines reach competitive speeds—validate with a press pilot.

Q: Do all films accept water-based inks?

A: No—PE and metallized films often need corona/plasma treatment or primers. Always test the actual film lot.

Q: How about migration risk?

A: Migration depends on formulation and package structure. Require finished-pouch migration and NIAS testing from suppliers.

Q: Is color vibrancy comparable to solvent/UV?

A: Modern pigments and profiling close the gap, but certain high-gloss or metallic effects still favor UV/solvent systems.

Q: Will wastewater handling be an ongoing cost?

A: Likely—evaluate wastewater treatment capex/opex. Often the VOC-compliance savings offset wastewater costs over time.