While it may sound easy to fill a spout pouch, a problem with package selection, equipment, or line setup will ultimately result in leaks, overflow, foam, or short shelf life.

This guide, delivered by Zhongjia Packaging, an expert flexible packaging manufacturer, covers what is important for three product families — food (sauces, purees), beverage (juices, RTD drinks), and “other” liquids (oils, syrups, liquid supplements) — and outlines simple steps to achieve consistent, leak-free fills.

Start by Defining the Product

The first decision is product-driven. Viscosity, particle content, temperature tolerance, and shelf-life needs determine everything that follows.

- Food (thick sauces, purees): high viscosity, may contain particulates. Needs wide-bore nozzles, positive-displacement pumps, and robust spout/weld reinforcement.

- Beverage (juices, RTD): low viscosity and oxygen sensitivity. Gravity or gear pumps work; aseptic or hot-fill options are often required.

- Other liquids (edible oils, syrups): low to medium viscosity with possible lubricating effects on seals; choose compatible sealant layers and test oil migration.

Always document the product’s viscosity, max particle size, pH, oil content, and target shelf life before you touch the line.

Match the Spout Pouch Design to the Product

Not every spout pouch works for every liquid.

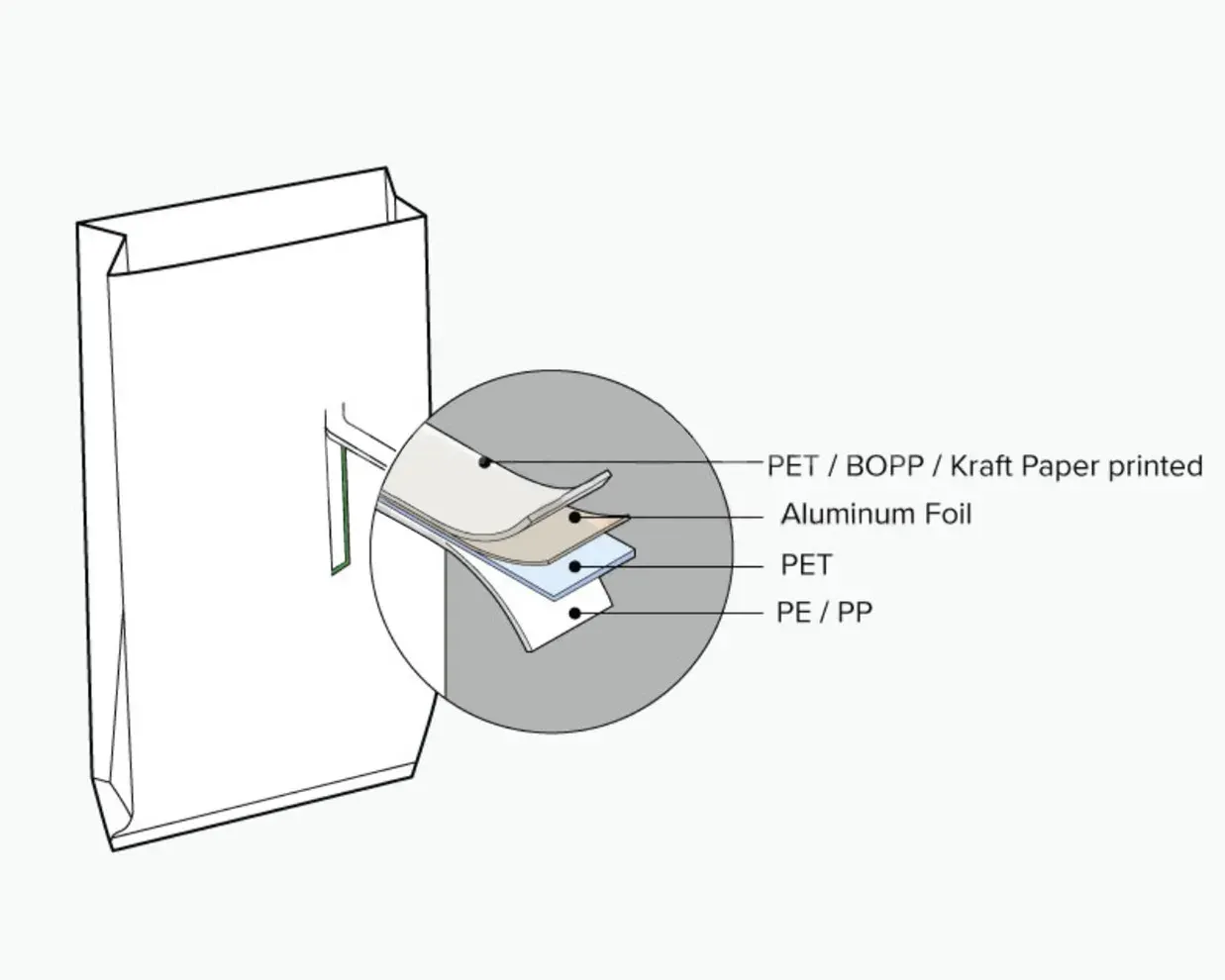

- Inner sealant: PE/CPP are common; select a sealant compatible with product chemistry (oil-resistant for edible oils).

- Barrier needs: EVOH or foil for oxygen-sensitive beverages; metallized PET for light-sensitive oils.

- Spout type & patch: choose spouts with buffer skirts or larger welding flanges for high-handling stress and oily products; the spout patch must be bonded to the flexible sealant layer, not to a brittle barrier film.

Design the pouch with a reinforced spout area and appropriate bottom geometry (stand-up vs. flat-bottom) for your SKU and fill line.

Choose the Correct Filling Method

Pump/nozzle selection is critical in filling the spout pouch:

- Gravity filling: best for thin, non-foaming beverages at high speed.

- Peristaltic / gear pumps: good for hygienic beverage dosing with moderate flow control.

- Piston/progressive cavity pumps: The Best Solution for Viscous Substances. Suitable for high viscosity sauces and particulate matter, it can minimize shear forces, ensure particle integrity, and achieve extremely high quantitative accuracy.

- Aseptic lines: required for long-shelf-life chilled or ambient beverages without preservatives.

Select nozzle bore size, anti-drip tips, and quick-disconnect fittings appropriate for product particle size and viscosity.

Set & Lock Process Parameters

Create a line recipe (documented, repeatable) for each SKU:

- Fill volume & tolerance: Define an acceptable ±g range and set the dosing control.

- Flow rate vs. line speed: Balance throughput with back-pressure to avoid splashing.

- Vacuum/back-pressure: Use vacuum or back-pressure control for foamy or carbonated products.

- Temperature: Hot-fill products need heat-resilient spouts and seals; adjust cooling/dwell time post-fill.

Record these parameters and lock them in the PLC/recipe system so operators reproduce the same settings every run.

Seal Correctly — It’s Not Optional

Sealing a spout pouch must weld the spout and film to the inner sealant layer. Common points:

- Hot-tack verification: Ensure the seal sets before the package leaves the station at production speed.

- Seal window: Find the optimal temperature/time/pressure for your laminate and lock it.

- Patch strategy: Reinforce spout welds with extra film or an added patch if product or handling stresses are high.

Run peel and burst tests on production samples to confirm seal integrity under expected storage and stacking loads.

Hygiene & Safety

Food and beverage fills require documented cleaning and contamination control:

- CIP routines for pumps and nozzles; sanitize spout fittings and caps.

- Allergen controls and line changeover protocols to avoid cross-contamination.

- Aseptic validation where needed — environmental monitoring and sterility records.

Inline QC and Finished-Sample Validation

Do not rely on film specs alone — validate filled pouches.

- In-line checks: weight checks, leak tests (vacuum/pressure/bubble), and visual cap torque inspections.

- Lab tests: finished-pouch MVTR/OTR, accelerated shelf-life, and sensory checks for aroma or off-notes.

- Pilot batch: run 500–2,000 filled pouches and perform distribution simulation (drop, vibration, compression).

Only approve full production after validation confirms shelf-life and seal performance.

Common Problems & Quick Fixes

- Foam/overflow: slow fill rate, use vacuum assist, or anti-foam dosing.

- Spout leaks: check spout weld location — move to inner sealant; reinforce patch.

- Incomplete seals: clean the seal area and re-optimize the hot-seal window.

- Inaccurate fills: recalibrate the pump or switch to a more suitable dosing technology.

Document each incident and corrective action in your batch record.

Conclusion

Filling a spout pouch reliably is an engineering and process discipline that starts with product definition and ends with finished-pouch validation. For food, beverage, and other liquid products, the keys are: match pouch construction to chemistry, select the proper dosing equipment, lock in repeatable fill/seal recipes, and always validate on filled samples under realistic distribution conditions. Follow that sequence and your line will move from firefighting to consistent, high-quality production.

About Zhongjia Printing

Zhongjia Printing stands as an expert flexible packaging manufacturer offering custom flexible packaging solutions tailored for diverse industries. Our production integrates water-based ink printing technology, combining high-definition visuals with eco-friendly performance. Every stage of manufacturing follows a strict QA protocol aligned with international standards, ensuring reliability, safety, and consistency across all packaging products.