Growing snack brands face a recurring choice: stay agile with short runs or commit to bulk custom runs that cut unit cost, improve shelf presence, and simplify logistics.

This guide, delivered by Zhongjia Printing, an expert flexible packaging manufacturer, walks procurement, product, and operations teams through a pragmatic path to a successful snack packaging solution — from format selection and materials to supplier RFPs and a pilot plan.

What “Bulk Custom Snack Packaging” Means and Why It Matters

Bulk custom snack packaging means ordering professionally engineered, branded film and converted pouches (or flow-wraps, sachets, bulk bags) in volume to gain lower unit costs, consistent quality, and predictable lead times. Drivers include margin pressure, retail listing requirements, DTC scaling, and sustainability targets.

When done correctly, a bulk approach reduces freight, shortens replenishment cycles, and elevates shelf impact.

Who Benefits — Size and Strategy Differences

- Small / DTC brands: Need flexibility — low-MOQ digital runs and short lead times; bulk buying can be phased (monthly or seasonal buys).

- Mid-size brands: Use a hybrid model — bulk for core SKUs and short runs for promotions.

- Large brands/distributors: Favor large-volume contracts with multiple SKU consolidations to unlock the best pricing and logistics efficiency.

Match procurement strategy to business cadence: a startup may pilot bulk for one hero SKU; an established brand may consolidate 10 SKUs into quarterly buys.

Core Formats and Best-fit Use Cases

Choose the snack packaging solution format that matches the product, channel, and fill-line:

- Pillow/Low Wrap packaging: designed specifically for ultra-high speed fully automatic filling lines, achieving the highest throughput and best suited for single-serving snacks.

- Stand up Pouch: A multifunctional flagship that provides excellent shelf appeal and resealability, suitable for multi-serving snacks and categories that require freshness preservation.

- Flat Bottom/Box Pouch: The preferred choice for high-end positioning, providing the largest front display area, and most suitable for gifts or applications that require stable support for display.

- Valve Coffee Bags with Unidirectional Exhaust Valve: Designed for large-scale production of roasted coffee beans, ensuring safe exhaust during freshness and shelf life.

- Stick Packs/Sachets: The best sampling, promotion, or precise single serving solution that effectively reduces the threshold for users to try.

- Bulk packaging bags (10-25 kg): Optimize the logistics volume-to-weight ratio for B2B secondary distribution and raw material supply.

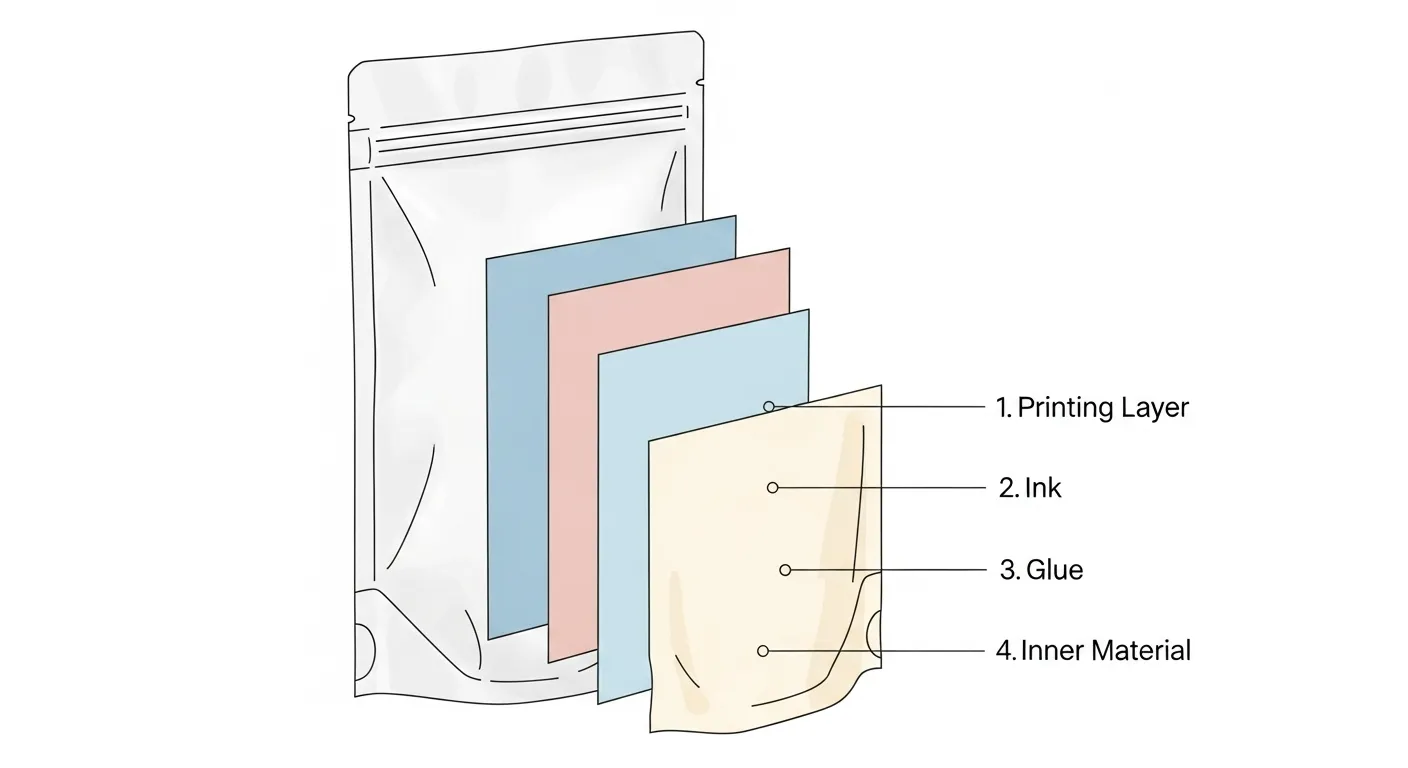

What to Customize — Materials, Structure, and Printing

Material selection: Performance-driven cost optimization. BOPP/PET is a high-quality printing substrate; VMPET/AL Coil is a high-barrier core. Mono-PE and r-Content solutions are highly recommended to meet global sustainability requirements.

Structural components: Enhance user experience and functionality. Customizable zippers/sliders, one-way exhaust valves, injection ports/suction nozzles, and handles. All functional areas can be designed with transparent windows and locally reinforced tear ports, balancing convenience and display.

Printing and Surface Treatment: Maximizing Shelf Influence. Provide options for gravure/flexographic/digital printing (linked to order quantity), as well as matte, high gloss, or partial effect processing. These decisions will directly affect the final unit cost and the recycling compatibility of packaging.

Engineering verification: Eliminate the risk of leakage. We strictly control the sealing width and thermal bonding window parameters, and reinforce the structure of the injection port/zipper area to ensure that your packaging has a leakage rate far below the industry average during transportation and use.

MOQ, Pricing & Ordering Models

Understand the cost drivers of the custom snack packaging solution:

- MOQs: Rollstock vs converted pouch MOQs differ; digital printing lowers MOQ but raises per-unit cost.

- Price drivers: Color count, film type, coatings, and specialty finishing.

- Ordering strategies: Tiered pricing (commit to volumes), monthly replenishment contracts, or combined-SKU production runs to dilute setup costs. Negotiate annual forecasts for better terms.

Filling Compatibility & Pilot Validation

Technical compatibility with filling lines is essential:

- Share hot-tack window, seal strength, and suggested machine parameters with your co-packer or filler.

- Run a staged pilot: empty rollstock → converted empty pouches → 500–2,000 filled pouches → shipment simulation and QA testing.

- Tests to require: finished-pouch MVTR/OTR, seal/burst/peel strength, grease resistance (for oily snacks), puncture and drop tests, and accelerated shelf-life runs.

How to Choose a Snack Packaging Solution Supplier

A capable supplier will reduce risk and speed scale-up. Look for:

- Vertical capabilities: extrusion, lamination, printing, and pouch conversion under one roof.

- QA lab: on-site MVTR/OTR, seal testing, and pilot support.

- Certifications: food-contact compliance (FDA/EU), ISO/GMP/BRC as relevant.

- Logistics & service: export experience, lead-time guarantees, sample policy, ability to dual-source.

- Commercial flexibility: small pilot runs, willingness to lock recipes, and clear warranty/defect policies.

Use a weighted scorecard (e.g., technical 30%, QA 25%, cost 20%, sustainability 15%, service 10%) to compare finalists.

Sustainability & Regulatory Considerations

Design for end-of-life: mono-material films (mono-PE, mono-PET) and reduced varnish coverage make recycling more feasible; r-content lowers carbon footprint but requires odor and performance checks.

Balance barrier needs (to prevent spoilage) with recyclability — in many cases, thin EVOH sandwiches or sol-gel coatings can offer near-foil protection with less material mass.

Ensure any eco-claims are backed by third-party evidence (MRF acceptance, COAs, chain-of-custody).

Quick Action Plan (Next Steps)

- Pick one representative SKU for a bulk pilot.

- Send an RFP to 3 qualified suppliers, including finished-pouch MVTR/OTR targets, seal window, and sample quantities.

- Run a filled pilot (500–2,000 packs), perform distribution simulation and QA tests.

- Score suppliers and negotiate an initial contract with forecasted volumes and safety stock terms.

- Scale with quarterly reviews for cost, quality, and sustainability metrics.

Conclusion

A well-executed snack packaging solution balances product protection, brand presentation, and supply-chain economics. Start small with a validated pilot, require finished-pouch performance data, and choose suppliers who combine technical depth with commercial flexibility — that’s the fastest route to lower cost, consistent quality, and faster time-to-shelf.

About Zhongjia Printing

Zhongjia Printing is an expert flexible packaging manufacturer now offering custom snack packaging solutions. With our own production facility, we deliver consistent quality through advanced water-based ink printing technology, offering vibrant results with reduced environmental impact. Each packaging roll and pouch is produced under a rigorous QA framework that meets international standards, ensuring safety, sustainability, and dependable performance for every client.