Launching a new biscuit SKU means more than a great recipe — it requires packaging that arrives on time, looks right, and preserves texture. For many brands, the biscuit packaging bag becomes the gating factor.

In this blog, let Zhongjia Packaging, an expert flexible packaging manufacturer, break the MOQ and lead time down for you.

Why MOQ and Lead Time Dominate Procurement Decisions

When procurement teams compare suppliers, unit price is visible; MOQ and lead time hide in the fine print. A tight MOQ lets small brands test flavors, but factories often impose higher minimums because of setup costs. If your biscuit packaging bag order forces you to hold a year of inventory, the nominal savings evaporate under storage, obsolescence, and quality risk.

The Physics Behind the “MOQ Wall”

Gravure printing — still the gold standard for consistent color on flexible films — has physical setup waste. The first 500–1,000 meters are essentially sacrificial as the press stabilizes. That sacrificial run means your biscuit packaging bag project must absorb a non-trivial setup overhead before you see sellable film.

Cylinder Investment: the Fixed-cost Barrier

A 7-color gravure job requires engraved cylinders, color approvals, and press proofs. Those plate costs create a fixed barrier that a single short-run biscuit packaging bag cannot economically cover. Understanding cylinder amortization helps you decide when to consolidate SKUs or move to alternative printing methods.

Material Master Rolls Define Practical MOQs

Factories order film in standard-width master rolls and plan lamination by roll yield. Your brokered MOQ often reflects roll geometry more than vendor generosity. When a biscuit packaging bag requires exotic film or foil, the effective MOQ spikes because the converter must commit full rolls to your job.

Digital Printing: Bypassing MOQs at a Cost

Digital printing eliminates plates and reduces setup waste, enabling low MOQs and rapid iterations. The trade-off: higher unit cost and constraints on certain finishes. For test runs or limited seasonal biscuit packaging bag editions, digital is often the smarter tactical decision despite the price delta.

The Design-to-plate Timeline: a Predictable Bottleneck

From artwork handoff to engraved cylinder typically takes 7–10 days for gravure. During this window, your biscuit packaging bag project sits in prepress — revisions here cascade into lead-time overruns, so finalize dielines and color specs before you brief the factory.

The Invisible Delay: Curing and Maturation

A “fast” lead time that skips adequate solvent evaporation or lamination maturation is not a badge of honor — it’s a food-safety and odor-risk flag. Proper curing (48–72 hours in many processes) stabilizes adhesives and removes residual solvents, ensuring your biscuit packaging bag won’t impart off-odors to fragile biscuits.

Production Queues and Seasonal Pressure

Chinese converters experience peak windows (pre-Chinese New Year, festival seasons) when laminators and gravure presses are fully booked. A supplier who can’t promise a slot jeopardizes your launch; confirm that your biscuit packaging bag order has a secured production window in writing, not a verbal estimate.

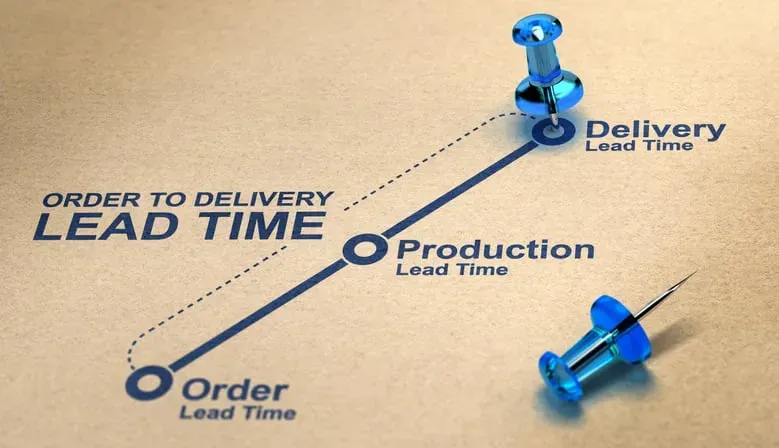

Logistics Extends the Factory Lead Time

Lead time doesn’t stop at the converter gate. Sea freight, customs processing, and inland delivery add weeks. When evaluating a supplier, calculate the effective lead time for a finished biscuit packaging bag delivered to your co-packer, and stress-test scenarios for expedited shipping.

Hidden Costs of Poor Timing: Stock-out Vs Dead-stock

Rigid MOQs can force brands into two bad outcomes: stock-outs (lost sales) or dead-stock (expired design stock). If your biscuit packaging bag becomes obsolete mid-season, creative relabeling won’t recover the brand damage and inventory carrying costs.

The Rush-job Penalty: Why Speed Can Cost Quality

Compressing lead time to meet a last-minute promotion often causes cutting corners: under-cured laminates, rushed seal checks, or reduced print QC. These shortcuts increase the risk of leaks and odor issues on your biscuit packaging bag, which can escalate returns and retailer friction.

Procurement Strategies to Compress Effective Lead Time

Practical tactics balance cost and agility. Aggregate demand across SKUs to hit roll minimums, use common back-layer laminates, and employ blank-stock with overprinting for flavor variations so your biscuit packaging bag runs share plates. These approaches reduce the per-SKU hit from plate costs and improve responsiveness.

The Rolling Forecast and Production Partnerships

A 3-month rolling forecast gives suppliers visibility and buys you priority scheduling. When a converter sees predictable volume for a biscuit packaging bag family, they can reserve roll stock and production slots, turning multi-week lead times into actionable windows.

Conclusion

MOQ and lead time are not immutable barriers — they’re variables you can manage with technical knowledge and supplier collaboration. For biscuit brands, the goal is a predictable rhythm: agreed plate amortization, validated curing schedules, and contractually protected production windows so your biscuit packaging bag supports market agility rather than blocking it.

About Zhongjia Printing

Zhongjia Printing is an expert flexible packaging manufacturer serving food brands with a reliable, repeatable supply of custom biscuit packaging bags. Backed by in-house gravure printing, lamination, curing, and strict quality control systems, Zhongjia Printing is structured to deliver stable lead times even during peak seasons.

At Zhongjia Printing, we support B2B buyers with end-to-end custom flexible packaging solutions, including material structures, printing methods, bag formats, and barrier performance tailored to biscuit texture and shelf-life needs. With technical R&D support and controlled production scheduling, we help brands balance MOQ, speed-to-market, and packaging consistency at scale.