Introduction

Many customers have encountered this issue: the packaging bags they receive seem perfect at first, but after storage, they begin to show signs of discoloration or unexpected changes. This phenomenon can be confusing and may impact product quality, especially in B2B packaging applications. Today, Zhongjia Packaging will explore the common pitfalls in flexible packaging and explain the “aluminum transfer” phenomenon in metallized films.

What is Aluminum Transfer in Flexible Packaging?

Not all bags experience this phenomenon, but it is most commonly seen in PET/VMPET laminated materials. In short, the issue can be summarized as: “the material is too rigid.”

VMPET films are made by metallizing a PET substrate with a thin layer of aluminum using vacuum deposition. PET is naturally a very hard material, which gives the laminated film excellent uprightness and strength. These materials are commonly used in stand-up pouches and solid packaging, especially for powders.

When two rigid layers are bonded together, any deformation may create small gaps between layers, which can lead to aluminum transfer, discoloration, and other issues over time.

Causes and Mechanisms of Aluminum Transfer

If we examine a laminated pouch, the structure typically includes three layers:

Printing layer

Water-based inks are often used for printing. These inks are softer than traditional inks, have larger molecular structures, and adhere better, reducing the chance of delamination.

Adhesive layer

Flexible adhesives, such as paper-to-plastic bonding glues, help prevent gaps and avoid pulling off the aluminum layer during storage or handling.

Aluminum layer

The choice of substrate is critical. Using DuPont 121 PET as the base ensures that the aluminum layer bonds tightly with the substrate, preventing discoloration and other defects.

By adjusting these three layers—printing, adhesive, and metallization—the risk of aluminum transfer can be minimized.

Effects of Aluminum Transfer

Aluminum transfer doesn’t just cause discoloration. It may also lead to several performance issues:

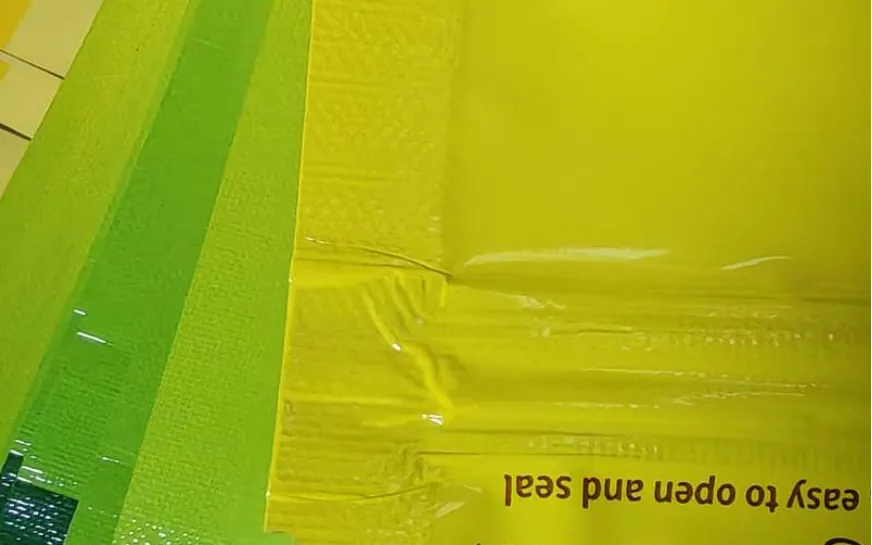

Wrinkling of finished products

If the adhesive layer cracks or the aluminum layer separates, it can cause tunnel-shaped wrinkles that affect the pouch’s appearance.

Decreased water and oxygen barrier properties

Gaps allow moisture and oxygen to penetrate, compromising the product’s shelf life.

Reduced adhesive performance

Over time, moisture entering through gaps can react with the adhesive, breaking down curing components and causing complete delamination.

Conclusion

Understanding aluminum transfer is essential for designing high-quality metallized packaging. By carefully selecting flexible inks, adhesives, and substrates, manufacturers can produce durable, visually appealing pouches that maintain their barrier properties over time.

Zhongjia Packaging specializes in custom, environmentally friendly flexible packaging solutions. With extensive experience in PET/VMPET laminates, water-based inks, and advanced adhesive technologies, we ensure high-quality pouches with minimal aluminum transfer risk. Our solutions provide low minimum order quantities, factory-direct pricing, and tailored designs to meet the unique needs of B2B clients worldwide.

For any questions about aluminum transfer or our flexible packaging solutions, feel free to contact us via email.