Sustainability is now an essential option for snack brands — it is a commercial requirement. As an eco-friendly packaging factory, Zhongjia Verpackung helps growing snack companies translate their sustainability goals into manufacturable, cost-effective packaging solutions.

In this article, Zhongjia Packaging is delighted to explain how we design eco-friendly snack food packaging that balances barrier performance, recyclability, and scalability for retail and e-commerce channels.

What “Eco-Friendly” Really Means in Snack Packaging

“Eco-friendly” is often misunderstood. From our factory perspective, true eco-friendly snack food packaging means reducing environmental impact across the whole lifecycle: material selection that supports local recycling streams, minimized material mass, verified recycled or bio-based content where feasible, and production processes, like water-based ink printing, that reduce energy and waste. It does not mean using paper solely for aesthetic purposes if the result compromises shelf life or creates additional food waste.

Material Strategies That Work for Snack Packaging

Practical material choices depend on product needs.

For chips and high-oil snacks, we commonly recommend high-barrier mono-polyethylene (PE/PE) constructions or thin EVOH laminates to achieve oxygen control while supporting mechanical recycling — a core requirement for eco-friendly snack food packaging in many markets.

For premium snacks seeking compostable claims, we evaluate PLA or certified compostable laminates only where local industrial composting infrastructure exists.

Design Rules That an Eco-Focused Factory Follows

When engineering eco-friendly snack food packaging, we apply three rules:

Prioritize food protection (barrier first),

Minimize material mass (downgauging without performance loss),

Choose the simplest recyclable stream (mono-material where possible).

These rules guide decisions on gusset design, seal geometry, and film thickness so brands don’t trade sustainability claims for higher spoilage or returns.

Printing and Converting: Sustainability at the Process Level

Ink and process choices materially affect the eco-credentials of eco-friendly snack food packaging.

We favor water-based inks, which is our priority now, and solvent-free lamination where substrate compatibility permits, because these reduce VOC emissions and simplify compliance.

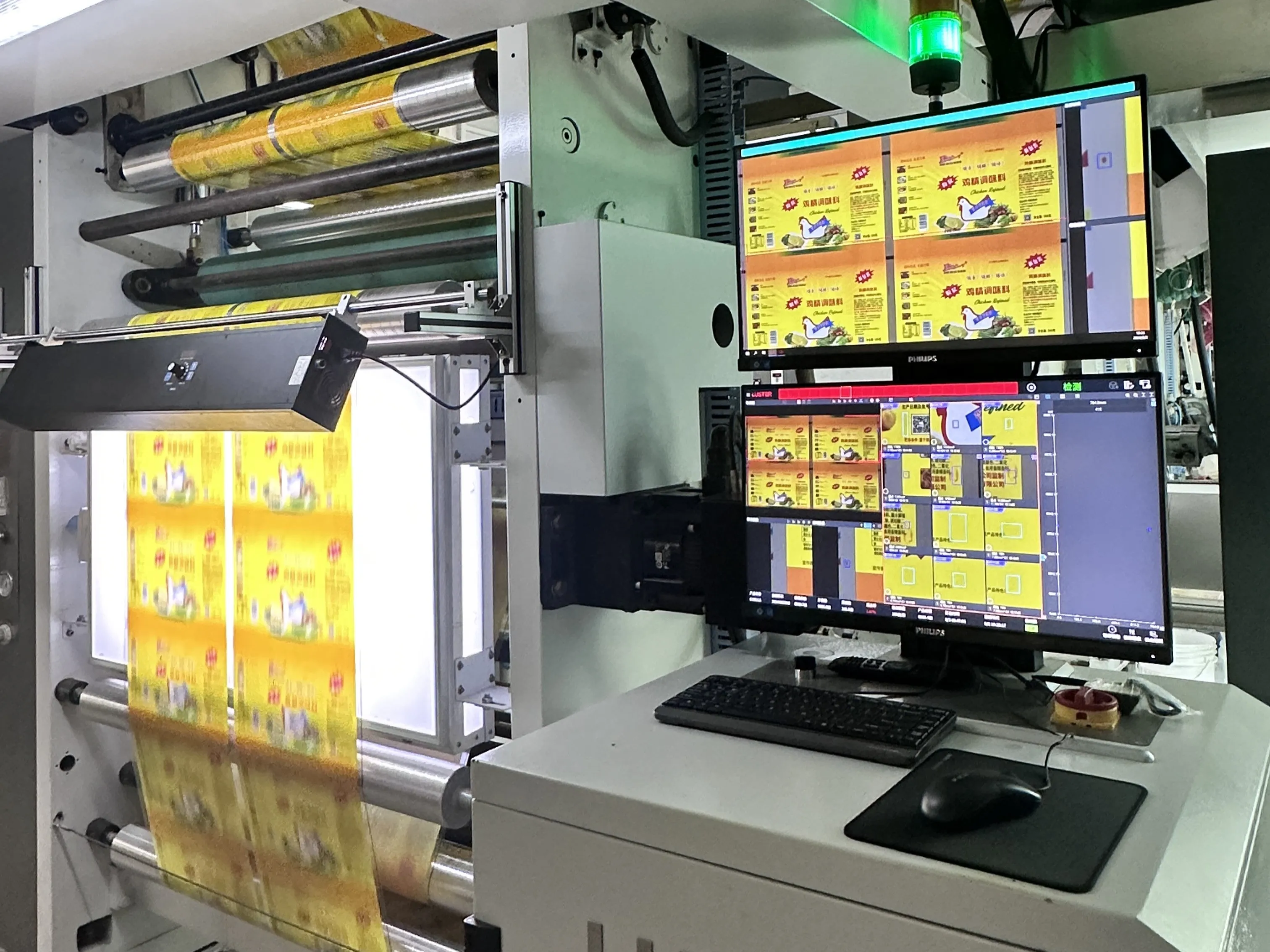

Digital printing is used for short runs and regional SKUs to cut plate waste and overproduction, while gravure or flexo remains the economic choice for scale with optimized ink laydown strategies.

Barrier Solutions Without Sacrificing Recyclability

Barrier performance can conflict with recyclability. Our factory addresses this by offering non-metallized high-barrier solutions (SiOx/AlOx coatings or EVOH laminates) and carefully engineered PE/PE barriers for shorter shelf lives. Each alternative is evaluated for its impact on the recyclability of eco-friendly snack food packaging, with third-party recyclability reports provided during supplier selection.

Quality Systems and Sustainable Production Practices

Eco credentials require consistent manufacturing discipline. We implement energy monitoring, solvent recovery where needed, and lean material usage to lower the carbon footprint of eco-friendly snack food packaging.

Our quality control ensures downgauged films meet puncture and seal standards, so reduced material use does not increase product failures.

Compliance, Certification, and Transparent Claims

Brands must substantiate sustainability claims. For eco-friendly snack food packaging, we supply layer-by-layer Declarations of Compliance, PCR certificates, and independent recyclability or compostability reports (TÜV/BPI). We also provide cradle-to-gate LCA summaries on request so brands can include accurate packaging footprints in ESG reporting.

Scaling from Pilot to Production Without Backsliding

Growing snack brands need capacity that scales.

We support staged scale-up: digital pilots, small gravure trials, then full-volume production with locked-in specs for eco-friendly snack food packaging.

This staged approach protects quality and ensures that sustainability gains (e.g., PCR content or downgauging) remain intact at scale.

How to Choose the Right Eco-friendly Packaging Factory

Ask prospective factories three focused questions:

Can you demonstrate eco-friendly snack food packaging that meets my shelf-life requirements with validated OTR/MVTR data?

Do you provide lot-specific compliance documents and LCA support?

Can you run pilot fills on my intended filler and produce scale economics?

A capable eco-centric factory should produce technical dossiers, pilot results, and a clear roadmap to scale.

Schlussfolgerung

For snack brands, eco-friendly snack food packaging is both a market differentiator and a risk management decision. The right factory partner integrates material science, print technology, and production discipline to deliver packaging that performs, scales, and substantiates sustainability claims. When brands treat packaging as a systems decision, they reduce waste, protect product quality, and unlock new retail opportunities.

Über Zhongjia Packaging

Zhongjia Packaging operates as an Experte für flexible Verpackungen, delivering Individuelle Verpackungslösungen für Snacks built on solid manufacturing fundamentals. Backed by in-house production, we translate brand concepts into packaging that balances shelf appeal, structural reliability, and practical performance.

Innovation is encouraged at every stage, particularly in our approach to eco-friendly snack food packaging, where Druck mit Tinte auf Wasserbasis is actively adopted to reduce environmental impact. With production processes aligned to internationally recognized safety and compliance requirements, Zhongjia Printing is a factory partner brands can rely on for responsible, forward-looking packaging development.