Sustainability in Packaging is no longer simply a marketing check box; it has become a company-wide system requirement. The sustainable packaging trend in 2026 is not just about the materials used to package products; instead, companies will need to take a holistic approach to making decisions about the film chemistry, printing technology, converting processes, and end-of-life management for their sustainable packaging products.

In this article, شركة زونغجيا للتغليف والتعبئة والتغليف, an expert الشركة المصنعة للتغليف المرن, summarizes the regulatory drivers, material innovations, printing developments (with a special focus on الطباعة المائية), circularity implications, and practical buyer actions—framed for procurement, R&D, and packaging decision-makers.

Why 2026 Is Different: Regulation, Retailers, and Investors

Three pressures are converging:

- Regulation: Extended Producer Responsibility (EPR) laws and the EU’s PPWR are forcing brands to demonstrate recyclability, recycled content, and clear end-of-life pathways.

- Retailer requirements: Major retail chains now include packaging KPIs in supplier scorecards; packaging failures block listings.

- Investor/ESG scrutiny: Scope-3 emissions and packaging footprints are investor metrics—brands that can quantify packaging sustainability reduce business risk.

Together, these drivers accelerate the sustainable packaging trend toward measurable, auditable improvements—beyond good intentions.

Material Innovation: Mono-materials, PCR, and Smarter Barriers

Material choices remain foundational for the sustainable packaging trend.

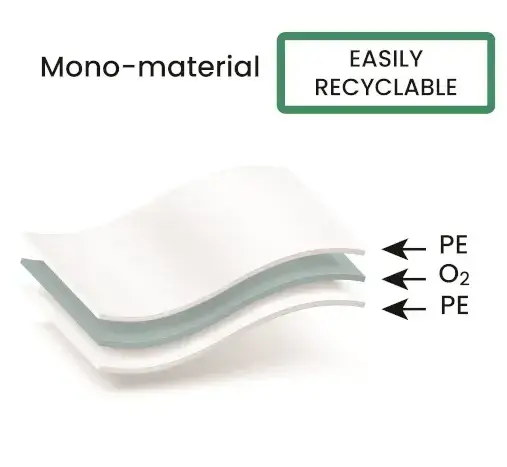

- Mono-material laminates (PE/PE, PP/PP) are replacing complex multi-layer laminates where possible. The benefit: improved mechanical recycling compatibility. The trade-off is performance—mono-materials often require gauge increases or active solutions (absorbers) to match barrier needs.

- Post-consumer recycled content (PCR) is moving from optional to required in many categories. Integrating PCR in food-contact layers demands validated migration and odor control strategies.

- Bio-based and compostable films are finding niche use where infrastructure supports them; their adoption is constrained by performance and verification gaps.

- Non-metallic barriers (SiOx/AlOx coatings, advanced EVOH architectures) offer a high barrier without metallization, improving recyclability or chemical recycling compatibility.

Selecting the right material is a balance: barrier performance, recyclability, cost, and supply stability.

Printing as a Sustainability Lever: VOC Reduction and Circular Design

Printing choices are now a technical control point for packaging sustainable trends and compliance.

Transition to Water-Based Systems

Water-based ink printing is the primary path for brands to slash VOC emissions and lower regulatory risk. Thanks to advances in high-efficiency drying و adhesion promoters, water-based inks now achieve competitive speeds and bonding on non-porous films. For supplements, specifying low-migration water-based systems is essential to ensure formula purity.

UV/EB Inks: Performance vs. Recyclability

While UV/EB inks offer superior precision, they are “thermoset” and can contaminate PCR (Post-Consumer Resin) streams. If specified, procurement should prioritize de-inkable formulations that can be removed during caustic wash recycling to maintain material circularity.

Digital Printing for Lean Inventory

Digital printing eliminates plate waste and enables right-sized short runs. This is a critical sustainability lever for high-SKU supplement lines, as it prevents inventory obsolescence and scrap from frequent label updates.

Design-for-Recycling Optimization

Procurement should incentivize design choices that lower chemical load:

- Reduce ink coverage and utilize negative space.

- Minimize white ink flood coats to improve NIR (Near-Infrared) sortability and reduce package weight.

Require ink-type disclosures, VOC data, and validated low-migration certificates (e.g., Swiss Ordinance) in all RFQs. Validated adhesion stability post-aging is mandatory to ensure brand integrity over the shelf life.

Circularity: Inks, Coatings, and the Recycling Process

Circularity is holistic. An otherwise recyclable film can be downcycled if inks or coatings contaminate the recycling stream.

- De-inking and wash-off issues: Some inks and varnishes hinder mechanical recycling or downstream repulping (for paper). Buyers must verify whether the intended ink/coating system is compatible with local recycling streams.

- Chemical recycling compatibility: Emerging chemical recycling technologies can tolerate mixed streams, but feedstock economics and scale remain constraints. Strategic partnerships with recyclers can de-risk large SKU transitions.

- Takeback and refill models: Refill pouches and reusable containers continue to expand in food and personal care. These formats demand durable printing and abrasion-resistant inks that maintain legibility through reuse cycles.

Procure with end-of-life in mind—ask suppliers for independent recyclability testing that includes the finished print and varnish.

Operational Levers: Energy and Waste

Sustainable packaging trends make a requirement for operation as well:

Process Energy and Thermal Management

Energy usage in drying and curing is a major cost and carbon driver. While water-based systems eliminate the need for energy-intensive VOC abatement (RTO), they require optimized drying profiles due to water’s high evaporative energy. Procurement should evaluate suppliers based on their press-level energy efficiency and use of renewable power.

Eliminating Changeover Scrap

Material waste during setup (overruns and solvent flushes) is a significant emissions source. Transitioning to digital or extended-gamut (7-color) printing minimizes startup scrap and chemical waste, especially for brands with high SKU complexity.

Use total-system KPIs (materials + process energy + logistics) rather than single metrics.

Certification, Claims, and Avoiding Greenwashing

Ask the brand for sustainable packaging trend claims.

- Request layer-specific Declarations of Compliance, PCR documentation, LCA, or EPD where available, and independent recyclability or compostability certificates (TÜV, BPI, OK Compost).

- Be specific in claims: “recyclable in PE film stream” is meaningful; “eco-friendly” is not.

- Align print claims with ink compliance docs—“water-based” must be backed by VOC data and low-migration testing if used on food contact packages.

Transparent, auditable claims protect brand equity and retailer relationships.

Buyer Checklist: 2026 Technical & Sustainability RFQ Gates

To catch up with the sustainable packaging trend, please examine the supplier:

- Layer-Level Transparency: Provide the full material specification (layer-by-layer polymers, adhesives, and coatings). Does this specific combination meet the RecyClass (EU) or APR (US) design guides for the target market?

- PCR Integrity: What is the percentage of Post-Consumer Recycled content? For food-contact layers, provide ISCC+ Certification or a Letter of Non-Objection (LNO) from the FDA/EFSA.

- Water-Based Ink Performance: Provide validated press run data on this specific substrate. What is the CO2e per 1,000 units associated with the drying process compared to your solvent-based baseline?

- End-of-Life Compatibility: Do the inks or functional barriers (e.g., AlOx/SiOx) interfere with NIR sorting or mechanical recycling? Provide independent lab reports (e.g., wash-off tests).

- Carbon Transparency: Provide a Cradle-to-Gate LCA (Life Cycle Assessment) or an Environmental Product Declaration (EPD) compliant with ISO 14040/44 standards.

- Operational Reliability: Define MOQ, lead times, and guaranteed yield rates. What is the expected scrap percentage during high-speed filler changeovers?

- Supply Chain Traceability: Can you provide Batch-level traceability back to the resin producer for both virgin and recycled content?

الخاتمة

The sustainable packaging trend in 2026 centers on holistic decisions: materials, inks, print methods, and end-of-life systems must align. Water-based printing has become mainstream, yet its benefits emerge only when paired with strategic material choices and proven recycling pathways. For B2B buyers, auditable proof—layer-specific data, migration/VOC metrics, and third-party recyclability tests—is critical. Treating packaging as a systems decision (not isolated) cuts regulatory risks, boosts supply chain resilience, and delivers measurable sustainability value.

نبذة عن شركة تشونغ جيا للطباعة

Since Zhongjia Printing was established, we have realized how important it is to catch up with the sustainable packaging trend. Without the self-possessed sustainable packaging technology, the company will be on a very slippery slope in the modern competition.

All of our wholesale flexible packaging bags and custom flexible packaging bags can benefit from this technology to reduce emissions and comply with local regulations.

Working with Zhongjia Printing to get:

✅Advanced Technological Strength

✅Rich Industry Experience

✅Efficient Production Capacity

✅Strict Quality Control

✅Flexible Customized Service

✅Global Service Network