Dans l'industrie alimentaire moderne, emballages alimentaires écologiques est devenu un élément clé de l'attention des consommateurs et des marques du monde entier. Les gens étant de plus en plus soucieux de l'environnement, la pollution environnementale causée par les matériaux d'emballage traditionnels devient de plus en plus évidente. Quels sont donc les matériaux qui composent les emballages alimentaires sur le marché ? Sont-ils respectueux de l'environnement ? Après utilisation et comment s'en débarrasser ? Aujourd'hui, rejoignez Zhongjia Packaging pour en savoir plus sur les meilleures solutions d'emballage alimentaire écologique.

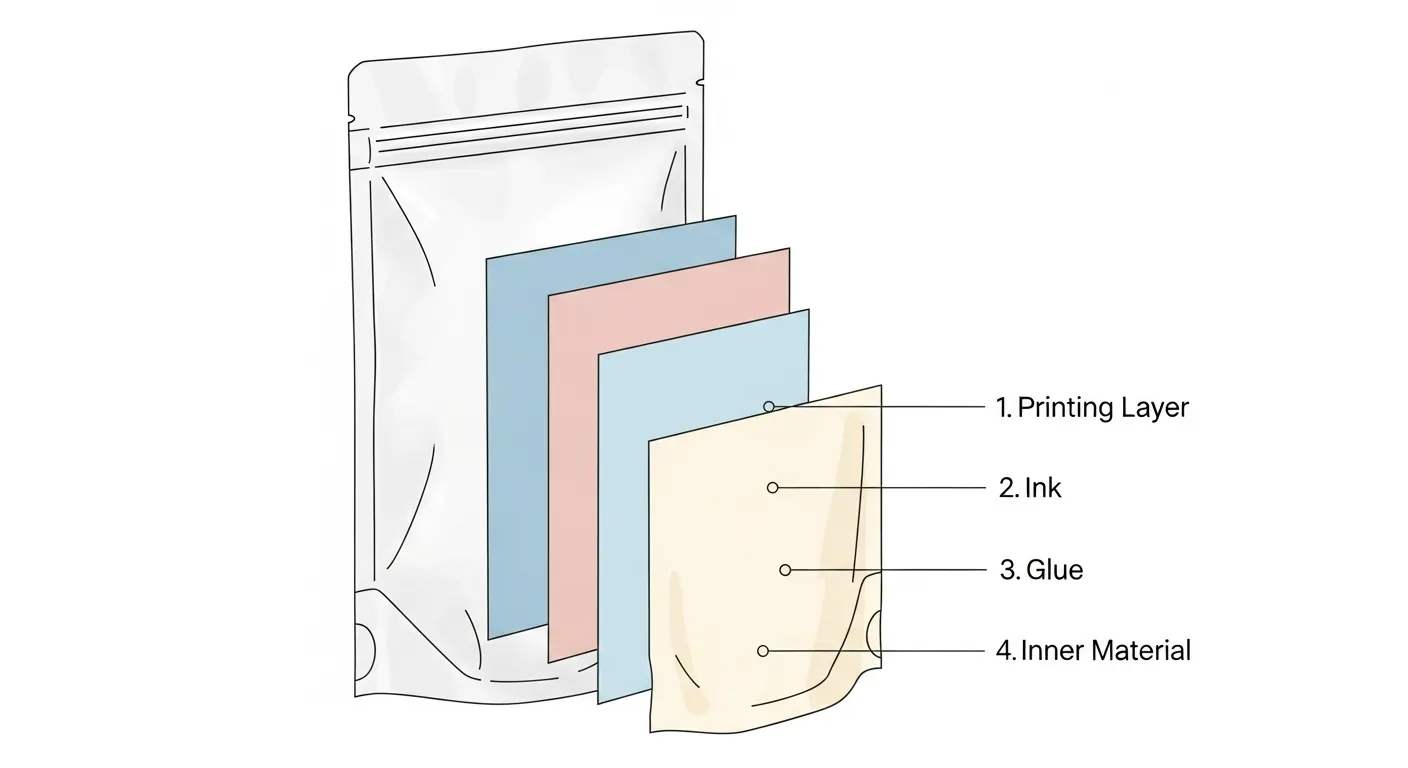

Démontage de la structure des sacs d'emballage alimentaire

Nous partons d'un structure commune de la pochequi peut généralement être divisée en quatre parties :

- Couche d'impression

- Encre

- Colle

- Matériau intérieur

Couche d'impression : Choisir les matériaux les plus respectueux de l'environnement

Les matériaux d'impression les plus courants sur le marché sont les suivants PET, NY, BOPP, etc. Parmi eux, le BOPP est le choix idéal pour les emballages flexibles respectueux de l'environnement :

- Le PET a une grande résistance et de bonnes performances d'impression, mais il n'est pas thermoscellable, ne peut pas être recyclé séparément, a un cycle de décomposition de plus de 200 ans et est extrêmement polluant pour l'environnement.

- Le BOPP est un matériau biodégradable et recyclable ; son essence est le plastique PP, qui peut être recyclé, extrudé à chaud, granulé et réutilisé d'autres manières, avec une bonne valeur de recyclage, c'est le matériau recommandé par l'usine d'emballages flexibles respectueux de l'environnement.

Encre : Encre à base d'eau est le choix de l'impression verte.

Trois types d'encres sont couramment utilisés dans l'impression d'emballages : l'encre UV et l'encre à base d'eau.

Encre traditionnelle :

Il contient beaucoup de solvants toxiques et libère des COV (composés organiques volatils) qui non seulement polluent l'air, mais peuvent aussi rester dans l'emballage, ce qui constitue une menace pour la sécurité alimentaire.

Encre UV

Bien qu'il n'utilise pas de solvants, le processus de durcissement par UV génère de l'ozone, ce qui présente un certain risque pour l'environnement.

Encre à base d'eau:

Le choix le plus respectueux de l'environnement ne nécessite que l'ajout d'alcool de qualité alimentaire, non toxique, non polluant et biodégradable, mais les exigences en matière de processus d'impression étant plus élevées, la maîtrise de la technologie de fabrication d'emballages souples respectueux de l'environnement est relativement faible.

Colle : La colle sans solvant est plus respectueuse de l'environnement

La colle est principalement divisée en :

Adhésif à base de solvant: Contient des solvants et libère des gaz nocifs pendant la production.

Adhésif sans solvant (Solvent-free Adhesive) : ne contient pas de composés organiques volatils, est ininflammable, sans danger pour l'environnement, ce qui en fait le premier choix pour les emballages écologiques.

Matériau de la couche intérieure : Sélection de structure PP recyclable

Dans le matériau de la couche intérieure, l'utilisation unifiée de plastiques recyclables tels que le CPP ou le BOPE avec la couche d'impression est la clé de la protection de l'environnement. Ces matériaux présentent de bonnes performances en matière de scellage à chaud et peuvent constituer une structure mono-matériau, ce qui favorise le recyclage ultérieur.

Deux structures idéales recommandées pour les sacs d'emballage alimentaire écologiques

En combinant les éléments ci-dessus, voici les deux structures respectueuses de l'environnement les plus représentatives sur le marché aujourd'hui :

✅ Structure I : BOPP + encre + colle sans solvant + CPP

- Couche d'impression : BOPP

- Encre : Encre à base d'eau

- Colle : Adhésif sans solvant

- Couche intérieure : CPP

Avantages : Excellente performance environnementale globale, recyclable, niveau élevé de sécurité alimentaire, adapté à la plupart des produits d'emballage alimentaire.

✅ Structure 2 : BOPE + Encre + Adhésif sans solvant (ou laminage) + BOPE

- Couche d'impression et couche intérieure : BOPE (structure mono-matériau)

Avantage : Extrêmement recyclable, convient à certains produits d'exportation nécessitant une certification de recyclabilité.

Inconvénients : Apparence limitée en raison d'une mauvaise adaptation à l'impression, faible précision d'impression, applicable uniquement à des groupes de clients spécifiques.

Zhongjia Packaging: Fabricant professionnel d'emballages flexibles écologiques

Zhongjia Packaging est un fabricant d'emballages flexibles respectueux de l'environnement, spécialisé dans les domaines suivants Impression à l'encre à base d'eau. Depuis sa création en 1996, Zhongjia Packaging s'est toujours engagé à fournir des solutions d'emballages flexibles personnalisables et hautement écologiques pour les industries alimentaire, chimique et du jouet. Nos avantages sont les suivants

🌿 Expert en solutions de matériaux respectueux de l'environnementLes objectifs de ce programme sont les suivants : maîtriser le processus de structure mono-matériau BOPP/BOPE et promouvoir les matériaux d'emballage recyclables ;

💧 Technologie d'impression à base d'encre à l'eau de pointeLes encres à base d'eau sont écologiques et non toxiques afin de préserver la sécurité alimentaire et de réduire les émissions de COV ;

🔧 Forte capacité de personnalisationLes produits de cette catégorie sont les suivants : l'adaptation structurelle, l'impression de motifs et le développement fonctionnel peuvent être réalisés en fonction des besoins des clients afin de répondre aux exigences de différenciation des marques ;

🏭 Propre usine, livraison rapideLe groupe de travail sur les emballages flexibles est composé d'équipements d'impression avancés et de lignes de production automatisées afin d'assurer une qualité stable et une livraison rapide ;

🌎 Expérience en matière d'exportation : nos produits sont exportés vers de nombreux pays et régions d'outre-mer, desservant plus d'une centaine de marques internationales avec une qualification complète en matière d'exportation.

Nous ne sommes pas seulement une usine d'emballages flexibles écologiques personnalisés, mais aussi un partenaire fiable dans votre stratégie de marque verte. Contactez-nous dès maintenant pour obtenir des échantillons d'emballages alimentaires flexibles à base d'encre à l'eau, et choisissez Zhongjia Packaging pour contribuer à la durabilité environnementale mondiale.

Conclusion

L'accent étant mis au niveau mondial sur les emballages respectueux de l'environnement, le choix de matériaux écologiques, de technologies vertes et de structures recyclables est devenu une tendance inévitable dans l'industrie de l'emballage.

Zhongjia PackagingEn tant que fabricant professionnel d'emballages flexibles respectueux de l'environnement, nous sommes prêts à explorer avec vous des solutions d'emballage plus durables. N'hésitez pas à nous contacter pour d'autres suggestions d'emballages écologiques et des services personnalisés !