Dans le monde moderne d'aujourd'hui, qui évolue rapidement, l'information se propage plus vite que jamais grâce à la technologie et aux médias. Pourtant, avant l'ère numérique, l'imprimerie jouait un rôle très important dans la communication de la culture et de l'information. Des anciennes gravures sur pierre aux feuilles de bambou, de la soie à l'invention du papier, la civilisation humaine n'a cessé de rechercher le meilleur moyen d'enregistrer et de transmettre le savoir.

Zhongjia Packaging est l'un des principaux fabricant d'emballages flexibles sur mesure avec des prix directs d'usine et la personnalisation de petites séries. L'une des technologies d'impression les plus avancées dans l'industrie de l'emballage que nous appliquons à Zhongjia est l'héliogravure. Voyons ci-dessous ce qu'est exactement l'héliogravure et pourquoi elle est importante dans la production moderne d'emballages souples.

Qu'est-ce que l'héliogravure ?

L'héliogravure - également appelée rotogravure - est un procédé d'impression supérieur par lequel l'encre est transférée des cellules gravées d'un cylindre métallique sur un substrat, qui peut être un film plastique, du papier ou une feuille d'aluminium.

- Plus simple à comprendre : Il s'agit d'un procédé qui consiste à tracer de minuscules sillons sur une surface, qui doivent être remplis d'encre. Lorsqu'une feuille de papier ou un film est pressé sur le support, l'encre contenue dans ces sillons se transfère à la surface pour donner une image bien définie avec beaucoup de détails. Le motif reste en permanence sur le matériau après le séchage.

C'est le principe selon lequel l'encre est retenue dans les zones en creux plutôt qu'en relief qui différencie l'héliogravure d'autres méthodes, telles que l'offset ou la flexographie.

Comment fonctionne l'héliogravure ?

Gravure sur cylindre :

Le dessin est gravé sur un cylindre métallique par une gravure laser ou électronique précise, atteignant des résolutions de plus de 2160 PPI pour une reproduction nette de l'image.

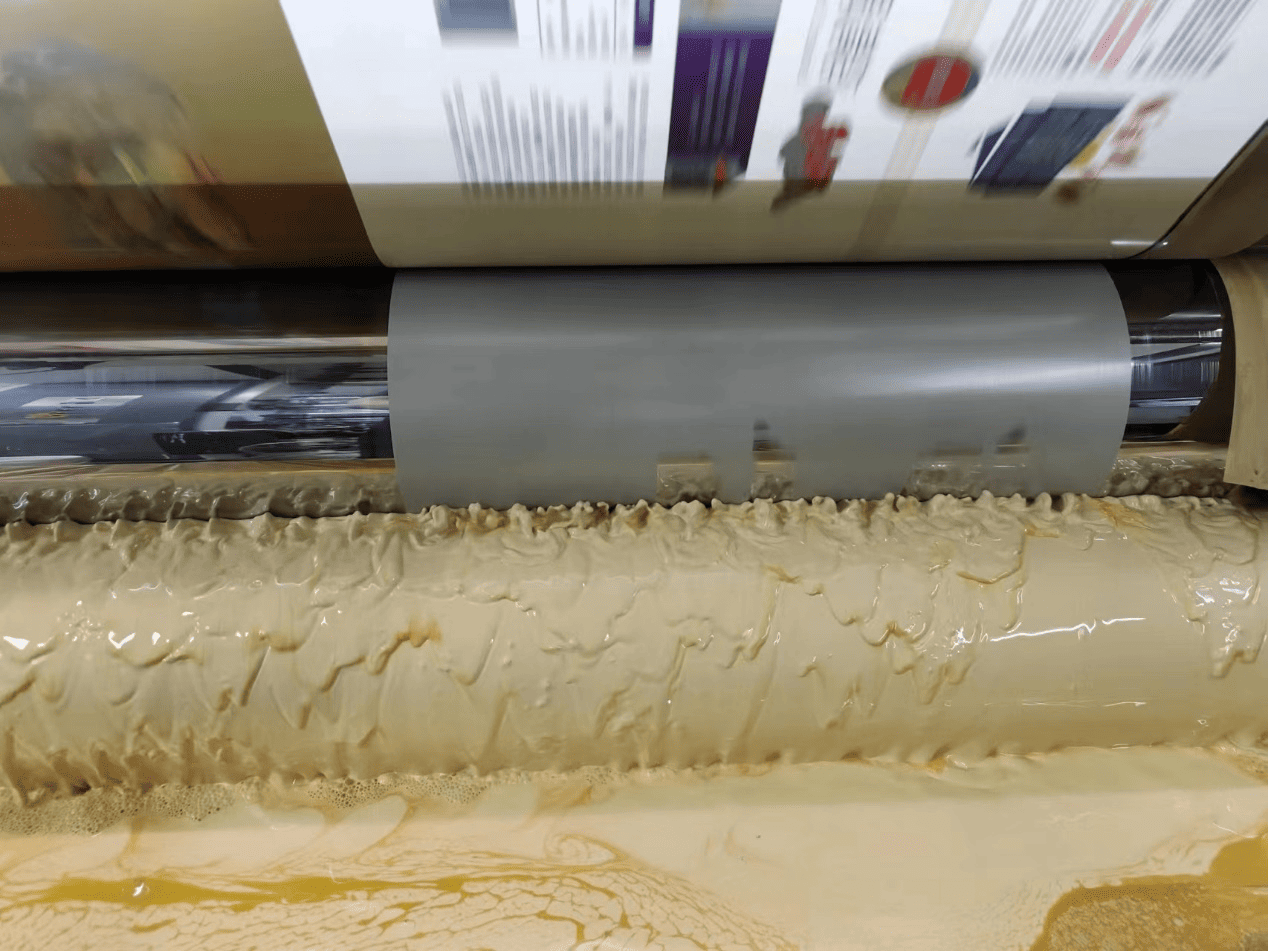

Application de l'encre :

Chaque cylindre correspond à une couleur spécifique (généralement dans le système CMYK : Cyan, Magenta, Jaune et Noir). Les cellules gravées sont remplies d'encre.

Suppression de l'excès d'encre :

La racle élimine l'excédent d'encre de la surface du cylindre, ne laissant de l'encre que dans les zones gravées.

Transfert d'images :

Le support, tel que le film plastique ou le papier, est pressé sur le cylindre rotatif et l'encre est transférée pour créer une image imprimée.

Séchage :

Le film passe ensuite dans un système de séchage à air chaud où l'encre est fixée.

Laminage et fabrication de sacs :

Après l'impression, plusieurs couches de film sont laminées ensemble pour assurer la résistance et les performances de barrière ; elles sont ensuite fendues et transformées en films pour sachets ou rouleaux, prêts pour la production d'emballages.

Pourquoi l'héliogravure est-elle idéale pour l'emballage souple ?

Haute précision

L'héliogravure permet d'obtenir une image fine et photoréaliste, aux couleurs homogènes, qui rend les emballages vivants et réalistes.

Excellente durabilité

La finition imprimée est résistante à l'abrasion, à l'humidité et aux produits chimiques ; elle est idéale pour l'emballage de produits alimentaires, de boissons et de produits chimiques quotidiens.

Rentabilité pour les grandes séries

L'héliogravure offre un coût unitaire compétitif pour la vente en gros à l'usine ou pour les commandes portant sur de grands volumes de production.

Compatible avec divers matériaux

S'applique à divers matériaux d'emballage tels que le PET, le BOPP, le CPP et le papier d'aluminium pour répondre de manière flexible à divers besoins en matière d'emballage.

Couleurs vives

En utilisant le système de superposition CMYK, il est possible d'obtenir des milliers de couleurs personnalisées pour répondre aux besoins uniques de conception visuelle des marques.

Zhongjia Packaging : Votre partenaire pour l'emballage flexible sur mesure

Fabricant professionnel de toutes sortes d'emballages souples personnalisés, Zhongjia Packaging associe une technologie d'impression hélio avancée à plus de 40 ans d'expérience pour offrir à ses clients des produits de haute qualité.

Nos services comprennent

- Personnalisation de petits lots pour répondre aux besoins des ventes d'essai de nouveaux produits ou de nouvelles marques

- Prix de gros direct de l'usine, idéal pour les commandes de gros volumes

- Service complet : consultation en matière de conception, impression, pelliculage et fabrication de sacs.

Qu'il s'agisse de l'emballage de denrées alimentaires et de snacks, de produits pharmaceutiques ou de produits de soins personnels, nous pouvons fournir les solutions d'emballage idéales pour que vos produits se distinguent dans les rayons.

Conclusion

L'héliogravure n'est pas seulement une méthode d'impression ; elle fait partie du processus de base de la fabrication d'emballages souples de haute qualité, durables et visuellement attrayants. Grâce à cette technologie, Zhongjia Packaging fournit en permanence des solutions d'emballage personnalisées de première qualité aux marques, en rendant la valeur du produit claire et attrayante pour les consommateurs.

Pour en savoir plus sur la façon dont l'héliogravure peut améliorer l'emballage des produits, contactez-nous dès aujourd'hui pour une consultation et un devis gratuits.